https://aarch.dk/wp-content/uploads/2022/03/arch4change-400x453-1.png

453

400

Niels Rysz

https://s3-eu-central-1.amazonaws.com/aarchdk/wp-content/uploads/2019/02/03164631/aarch-logo-dark.svg

Niels Rysz2022-03-09 14:11:062023-11-16 09:40:11ARCH4CHANGE: A new ressource for learning and teaching sustainable architecture

https://aarch.dk/wp-content/uploads/2022/03/arch4change-400x453-1.png

453

400

Niels Rysz

https://s3-eu-central-1.amazonaws.com/aarchdk/wp-content/uploads/2019/02/03164631/aarch-logo-dark.svg

Niels Rysz2022-03-09 14:11:062023-11-16 09:40:11ARCH4CHANGE: A new ressource for learning and teaching sustainable architecture19.09.2022

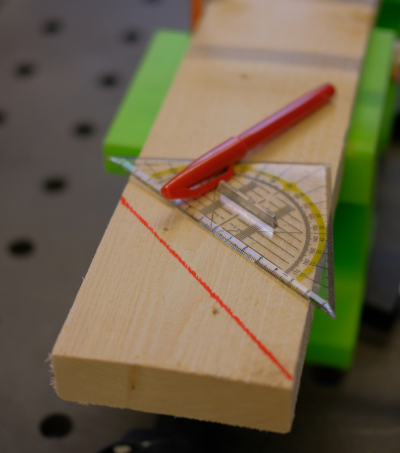

In a few years time, workers at construction sites may get company in the form of a new type of employee: the robot. Jens Pedersen’s PhD project aims at creating a user-friendly solution that allows craftsmen to give robots instructions simply by drawing directly on the piece of wood that needs to be cut.

A marker, a piece of wood and a robot. It is possible that, in a few years’ time, these three ingredients will make it possible to adjust a piece of wood at the construction site.

Today, we first have to draw a model on a computer; the robot then cuts the wood based on this model. However, Jens Pedersen’s industrial PhD project is working on a solution that is intriguing in its simplicity: you draw directly on the timber with a marker, and the robot then cuts the wood along the line.

‘A solution to this problem would really open up the building industry, as it would make robots accessible and easier to use without any need for specialised knowledge’, says Jens Pedersen.

GOING INTO THE CODE

What is most needed to realise the project with the working title Parawood – On-site Parametric Robotic Fabrication of Timber Constructions is programming. For this reason, Jens has spent many hours writing code. He is a self-taught programmer and has had experience as a computational designer at AKT II, in London, where he, among others, advised BIG and Heatherwick on the construction of the new Google headquarters in Charleston, San Francisco.

The next stage involves user testing of the newly developed software with students from Aarhus School of Architecture, and others, in the school’s workshop facilities.

‘Our aim is to give the software platform an uncomplicated user interface that does not require specialised knowledge. This will make possible on site adaptation of the timber at the construction site. For architects, this may affect the very design process, as robots can then suddenly become part of the sketching process.’

LOWER COSTS AND MORE DETAILS

In addition to wood being cut on site, the manufactured parts will also be numbered and shaped, so there will only be one single way of joining them together. Prototypes developed by Jens have shown that this approach can save both time and money during the joining process.

‘The fact that we will be able to use robots right at the construction sites will result in reduced construction costs and also allow a higher level of detailing’, Jens explains.

A PROJECT RIGHT ON TIME

The project is carried out in collaboration with Odense-based company Odico, who precisely work with robotics for the construction industry. And a patent application for Jens’ software solution has already been filed.

MÅSKE ER DU OGSÅ INTERESSERET I DETTE

Radical Sustainable Architecture

Radical Sustainable Architecture